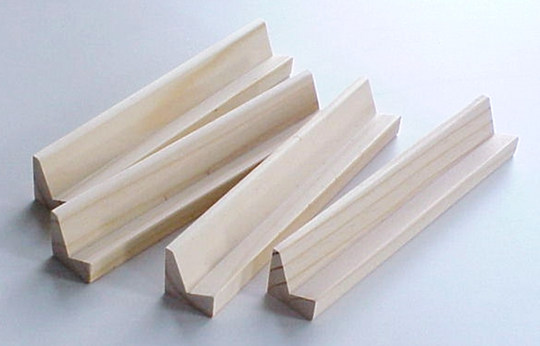

This is a set made of pine, shown here sanded with no finish.

This is the natural color of the racks, they were sanded with 320 grit, wet down, sanded again with 400 grit, and now they are ready to stain, seal and varnish - or play. They are so smooth, they need no finish and will age into a soft light pine color.

When finishing wood it helps to wet the wood down and let it dry before sanding. The loose grain ends on the surface will stand up and are easier to sand away. Finer grits of sandpaper are normally used on metal finishing, but I always used 400 grit paper before starting the staining process because staining the wood lifted the grain again and without that smoothly sanded surface to start with. Sanding off the rough grain raised by staining was a lot more work. Pine is a more porous wood than the hardwoods you may work with and the sealing step is critical to ending up with a smooth and long lasting finish. Finer grits offer a better finish.

Your wood finishing skills are as important as the rest of of the work that goes into creating anything with wood. A beautiful table badly finished gives the impression of a badly made table. Finishing is as much a craft as designing, measuring, cutting and assembly and it gives people their first impression of the quality of your work. It pays to take time and prepare your wood for a fabulous finish by doing a great sanding job first. We recommend using these wet or dry sanding products because they hold up better than most plain wood sandpaper and they offer finer grits that give you a surface ready to do its best.

Click to see the Wet/Dry sandpaper selections

Back to the Start Page

IF you use these links to order, I will earn a small commission. This does not change the price you pay, it costs the same whether I am paid or not. I tell you this because I am recommending some products here and the FTC requires that I tell you. PS - You may notice we have no ads on this site and your help is highly appreciated!

copyright© 2001 - 2026 dominotables.net all rights reserved.

use of this site indicates your acceptance of our policies

more information in our privacy policy